At the Prospectors & Developers Association of Canada (PDAC) Convention 2025—the world’s premier mineral exploration and mining event—KPI Mining Solutions participated in the technical session Level Up Your Project Reserves Against Uncertainty and Risks. One of the key topics we addressed was a common misconception: What exactly is stochastic mine planning?

The term stochastic can seem intimidating, especially to investors and professionals from other engineering disciplines. However, the concept behind it is both powerful and essential for making smarter decisions in mining.

The Problem with Traditional Mine Planning

Mining is uniquely influenced by geological uncertainty. As Jean-Michel Rendu [1] stated:

“The main difference between mining risk and the risk associated with projects in other businesses is the geologic component. Geology defines the location of mineral deposits, the properties of these deposits, whether they can be mined safely, and whether minerals of economic value can be feasibly extracted.”

No matter how much drilling is done, complete knowledge of a mineral deposit remains unattainable. Even with grade-control data during production, uncertainty persists. Additionally, fluctuating metal prices, varying recoveries, equipment performance, and unpredictable operational conditions all introduce further variability.

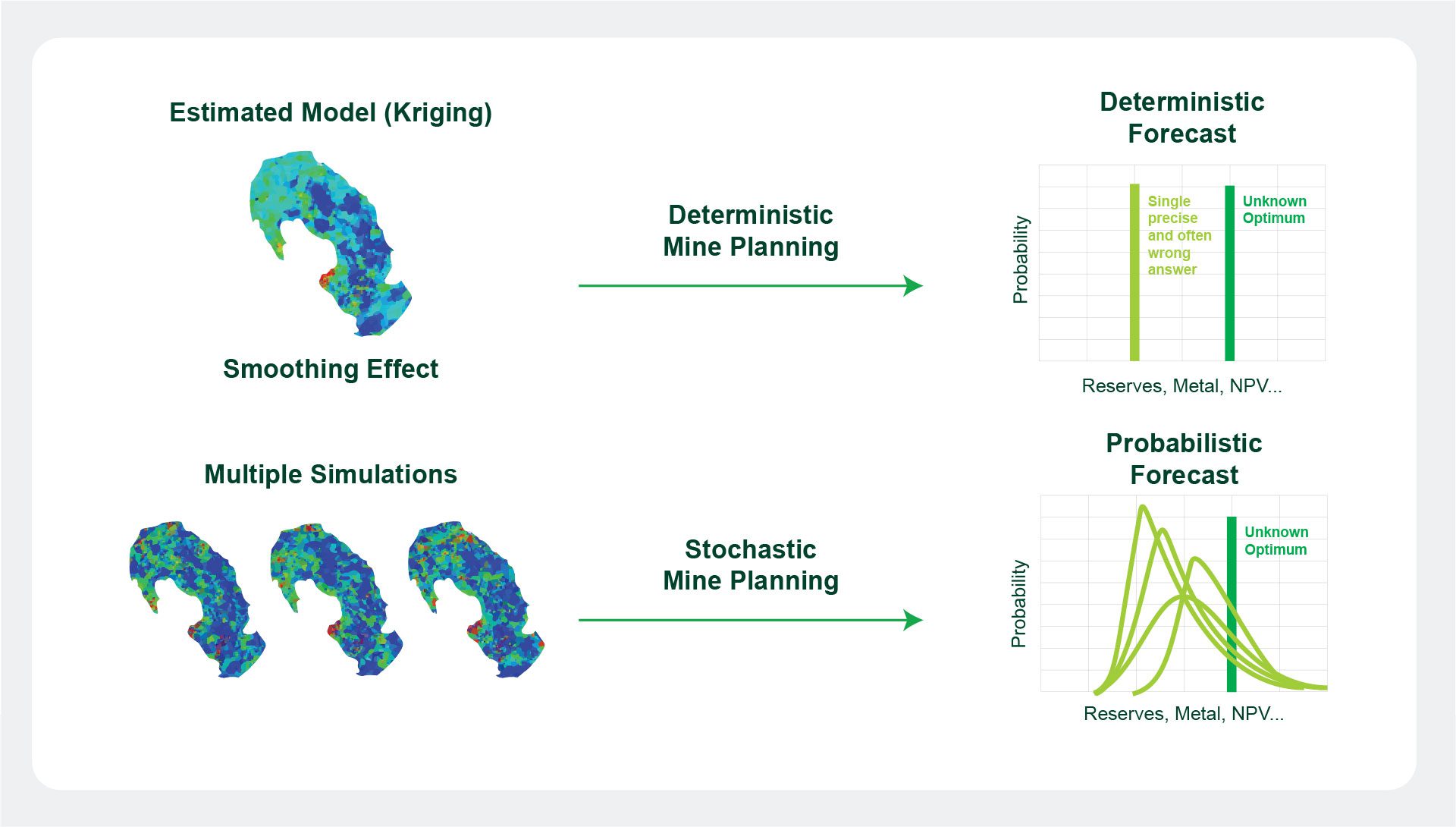

Why Deterministic Thinking Falls Short

Many studies confirm that relying on a single estimated resource model—a deterministic approach—is a major cause of technical risk in mining. By assuming a single forecast is accurate, mining companies expose themselves to unexpected losses, missed opportunities, and flawed investment decisions.

The Stochastic Mine Planning Advantage

Stochastic mine planning acknowledges uncertainty instead of ignoring it. Rather than relying on a single fixed outcome, it leverages probability distributions to account for multiple potential scenarios. As the saying goes:

“It’s better to be approximately right than precisely wrong.”

Since the absolute truth about a mineral deposit is unknowable, probabilistic forecasts provide more realistic, risk-aware insights. Unlike traditional deterministic models, stochastic mine planning delivers a comprehensive view of possible outcomes.

What is not Stochastic Mine Planning

However, having improved resource models is just the first step. Many mining professionals ask:

Common Misconceptions About Stochastic Mine Planning

Despite its advantages, many mining professionals misunderstand how to apply stochastic approaches. Here are five misconceptions we frequently encounter:

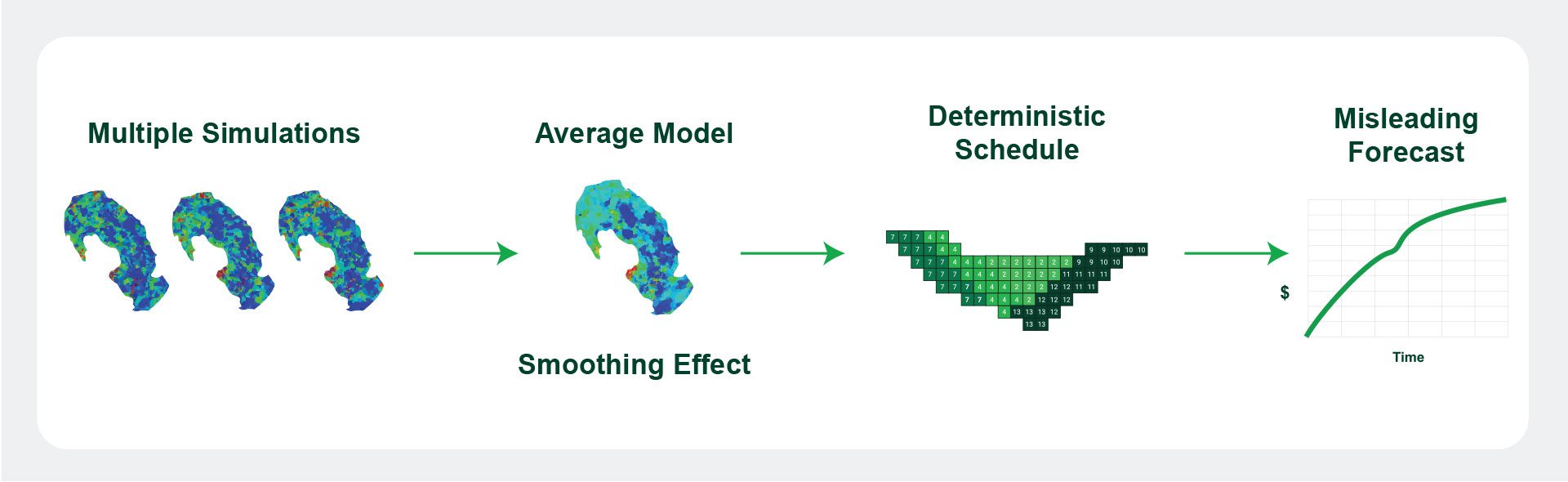

“Let’s Take the Average of the Simulations”

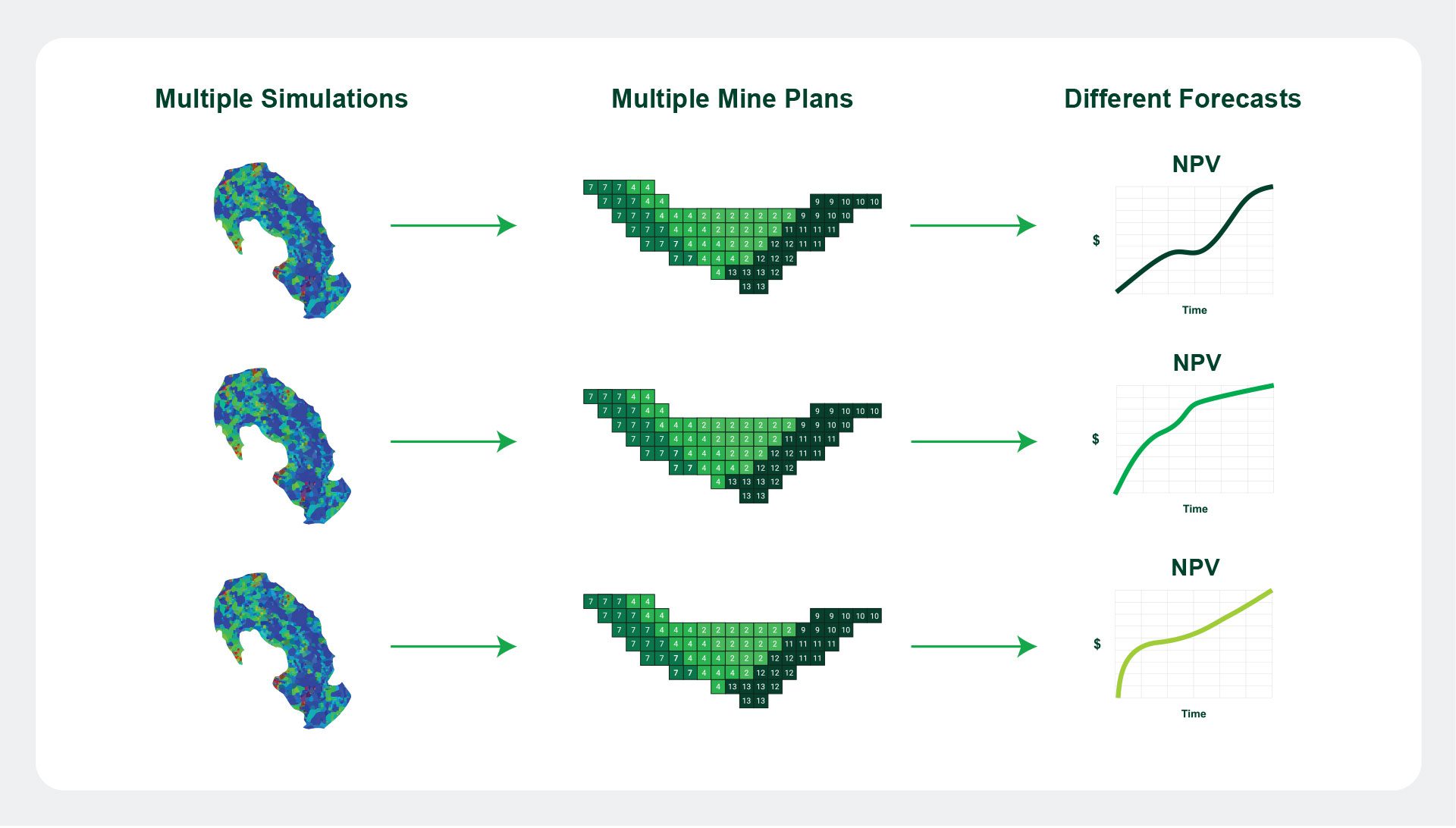

“Let’s Generate One Mine Design and Schedule for Each Simulation”

Another flawed approach is creating a separate mine design and production schedule for each simulation. This results in multiple conflicting plans with no clear execution strategy. Mining operations need one robust plan, not fifty competing ones.

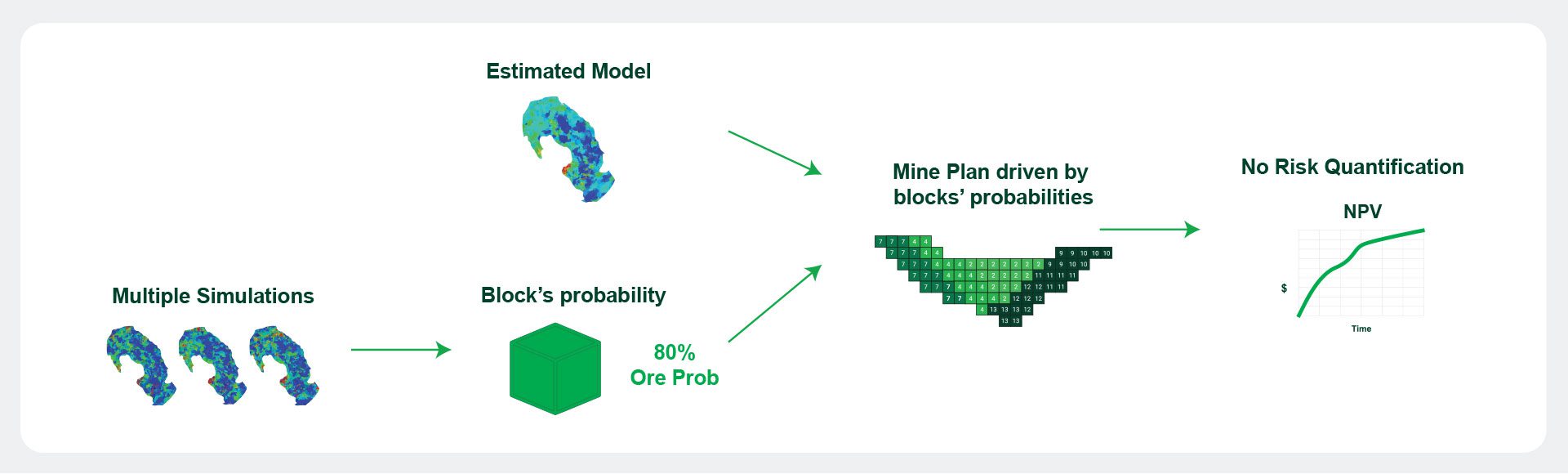

“Let’s Use Simulations to Calculate Probabilities for Each Block”

While probability-based approaches provide useful insights, they still fall short of fully integrating uncertainty into mine planning. They often:

How Stochastic Mine Planning Works

So, can we generate a single mine design and production schedule while considering all simulations at once?

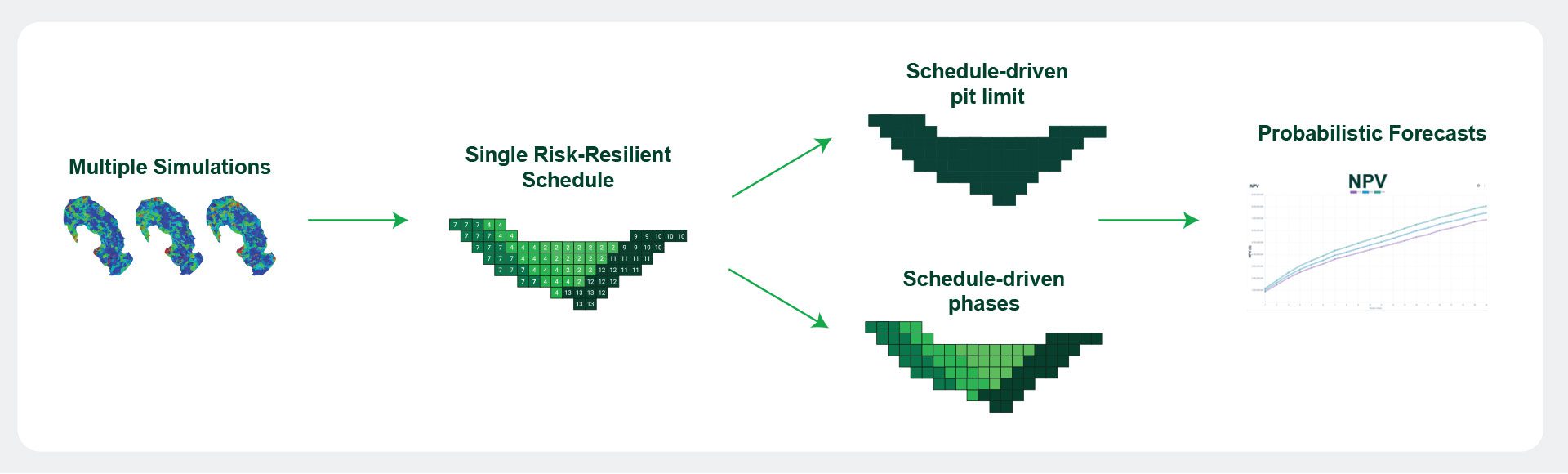

Yes—and this is exactly what stochastic mine planning does.

The key to effective stochastic mine planning is integrating uncertainty directly into mine design and scheduling. Rather than averaging simulations or generating multiple conflicting plans, stochastic optimization produces a single, risk-resilient mine plan that dynamically adapts to all possible scenarios.

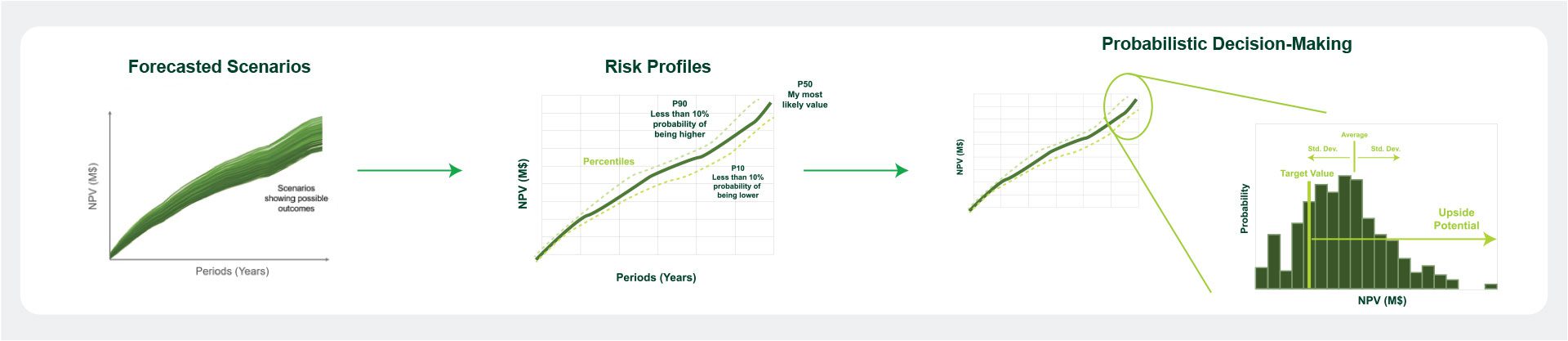

With stochastic mine planning, forecasts aren’t limited to a single estimate—they include probabilistic ranges for cash flows, tonnages, grades, recovered metal, waste tonnages, and more. This approach enables mining companies to make more informed, risk-aware decisions.

Maximizing Value Through Stochastic Optimization

Stochastic optimization in mine planning has two main objectives:

Maximizing Net Present Value (NPV)

Traditional methods assume each block is mined independently with a predefined destination. This means optimizing the discounted cash flows generated from the value of products sold across the value chain while minimizing operational costs, capital expenditures (CAPEX), and other expenses.

This often leads to suboptimal decisions. In contrast, stochastic optimization maximizes value across the entire mining value chain, optimizing final product value rather than individual block economics.

Risk management in stochastic mine planning involves two key components:

By balancing these objectives, stochastic mine planning creates a resilient, high-value mine schedule that proactively manages uncertainty.

Debunking Another Myth: “Let’s Minimize Variance in Production Metrics”

Some assume that stochastic mine planning aims to minimize production variance. However, this approach can be counterproductive. Minimizing variance would penalize high-grade areas, leading to suboptimal schedules. Instead, stochastic mine planning ensures production targets are met while maintaining flexibility for maximum profitability.

The Proven Value of Stochastic Mine Planning

At KPI Mining Solutions, we have seen firsthand the transformative impact of stochastic mine planning across various projects. Our findings align with research from the COSMO Stochastic Mine Planning Laboratory at McGill University [2].

This approach provides a more robust framework for decision-making, offering insights into the probabilities of success and risk that traditional methods simply cannot deliver.

This last benefit is especially valuable for investors. Rather than relying solely on NPV estimates, investors can assess both the upside and downside potential of mining projects.

Stochastic mine planning is not just an advanced modeling technique—it is a paradigm shift in how mining companies approach decision-making. By generating a single, risk-resilient production schedule, it provides a more reliable framework for resource management and investment planning.

We strongly encourage resource modeling and mine planning experts to explore stochastic mine planning for its tangible benefits in profitability and risk management. Likewise, decision-makers and executives should challenge technical teams to adopt this approach, ensuring they unlock the full potential of their mining assets.