The first truly stochastic & simultaneous optimization software for mineral value chains.

Increase the life-of-asset net present value by

up to 40%.

Key Features

Simultaneous stochastic optimization

Simultaneously optimize the strategic production plan of your mineral value chain, (e.g. open-pit mines, stockpiles, dumps, plants and more) with complex material flows and transformations.

Geostatistical and other Monte Carlo simulations

Use orebody simulations (grades, material types, geometallurgical properties, etc.) as well as simulations of metal prices, equipment indicators, and more.

Schedule-driven optimized pit limits

Obtain truly optimal pit limits for multiple open-pit mines instead of defining the pit limits in advance, separately for each mine.

Simultaneously optimized cut-off grades

Optimize cut-off grades integrated with the extraction sequences, multiple processing streams, stockpiling/reclaiming operations, etc.

More sustainable schedules

Integrate the optimization of waste management, acid rock neutralization, and other environmental aspects in the same model.

Modeling of complex cost and revenue structures

Model complex functions for cashflows, revenues, fixed and variable operating costs to drive long-term optimization process.

Practical block-based extraction sequences

Obtain extraction sequences that better represent the mining selectivity while accounting for multiple mineability constraints (slope angles, mining width, and more).

Risk-managed production schedules

Generate more reliable production schedules by managing the risk of not meeting annual production targets.

Probabilistic reporting dashboards

Generate and visualize probabilistic reports for all production forecasts (cashflows, grades, tonnages, costs, etc.) and assess the year-over-year chances of meeting production targets.

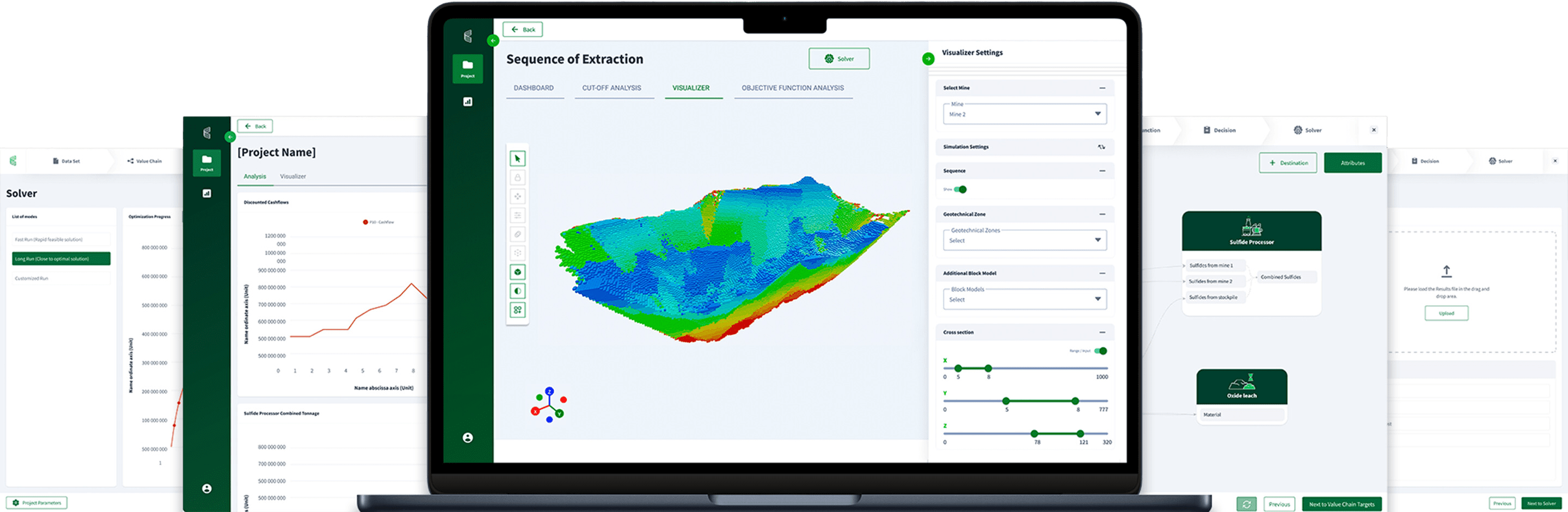

3D visualization

Visualize and compare the optimized sequences of extraction, pit limits, and geostatistical simulations of your multiple open-pit mines.

Benefits of KPI-COSMO vs. Conventional Mine Planning Software.

Simultaneously optimize your whole production schedule.

Production forecasts that better meet production targets.

Up to 25% larger optimized pit limits and higher recovered metal.

Frequently Asked Questions

Outcomes

Besides the maximization of life-of-mine NPV, the stochastic mathematical model of KPI-COSMO has a risk management component. By using the simulations of multiple sources of uncertainty (geologic or economic), KPI-COSMO allows for minimizing deviations from multiple production targets of the mineral value chain as well as advancing the extraction of less risky areas and delaying riskier areas during the life-of-mine. This differs from conventionally generated mining production plans that are unable to manage the technical risk and hence, usually struggle to meet the planned production targets. As a result, in addition to higher NPV, KPI-COSMO provides more risk-managed long-term production forecasts.

Sensitivity analysis is a standard practice in mine planning. This approach usually consists of applying different increasing or decreasing factors to one or a set of input parameters used in the mine planning process. This approach is valuable to assess the value drivers and bottlenecks across the mineral value chain. The main limitation of the sensitivity analysis is that it does not provide probabilistic reporting of the generated mining production plan. For each sensitivity scenario, a new solution is generated, and we need to select the best scenario based on certain metrics. Some questions cannot be answered based on sensitivity analysis for a given mining production plan: “What is the chance of reaching the mill capacity in the first year?” “How sure can we be that the quality of the produced concentrates will meet the contracted targets?” “Which years of production will be problematic in terms of deleterious metals?”. The stochastic framework of KPI-COSMO also allows the user to perform the sensitivity analysis. The scenarios (simulations) of different sources of uncertainty are crossed against the optimized mining production plan generating a probabilistic reporting of the multiple production forecasts. The risk assessment of KPI-COSMO, thus, provide a significantly more informed report for the decision-making process.

Inputs

The estimation methods, such as the multiple variants of kriging, inverse-distance, etc., generate a smooth representation of the mineral deposits. That is, low values are overestimated, whereas high values are underestimated. This smoothing effect has serious adverse effects on the scheduling optimization process that is highly influenced by the connectivity and proportions of high grades, where we make money. The geostatistical simulations, on the other hand, honor the data at their location, reproduces statistics (mean, variance, histograms, variograms, and potentially high-order statistics) of the exploration data. The simulations are equally probable realizations of the mineral deposit and provide a quantitative measure of its spatial uncertainty. Hence, they are improved inputs for the long-term mine planning process. The same simulations also allow for managing the risk of not meeting production targets on KPI-COSMO and enable outputting probabilistic long-term production forecasts for the mineral value chain.

The main inputs for the optimization process of KPI-COSMO are a set of geostatistical simulations of the mineral deposits of your value chain. There are some orebody modeling software tools available in the market that offer efficient conditional simulation algorithms for continuous and categorical variables (e.g., a single grade or multiple correlated grades, material types, weathered facies, geometallurgical properties, etc.). Once these simulations are properly generated and validated against the drillhole data, they can be inputted to KPI-COSMO for the simultaneous stochastic long-term production planning optimization of a mining complex.

15-20 simulations are sufficient to generate stable long-term mining production plans as various case studies have demonstrated. In each year of production, several hundred to a few thousand mining blocks are scheduled to be extracted. This grouping of scheduled mining blocks represents a massive change of support, and due to variance-support relations, the solutions converge fast with the number of simulations.

Sequence of Extraction

The conventional pit limit algorithms, such as L&G, Pseudoflow, etc., cannot take into account the time value of revenues and costs. The final pit shell is subjectively selected by the mine planner based on different criteria, which may include a rough discounting based on two non-practical schedules named as best (pit-by-pit) and worst (bench-by-bench) cases. In addition, these conventional algorithms are based on economic value of mining blocks, which (a) assume predefined destination for the blocks, (b) do not consider the material blending and transformation across the mineral value chain, and (c) neglect the uncertainty and variability in grades and material types within the deposit. The long-term production schedule should yield the optimal pit limits, and not the other way around, and this can be achieved with KPI-COSMO.

Different aspects contribute to the larger pit limits generated by KPI-COSMO. First, the geostatistical simulations provide a significantly better representation of the spatial distribution of high grades within the mineral deposits. Second, the scheduling of high-grade mining blocks opens up the opportunity to economically extract some low and medium grade blocks throughout the sequence of extraction. Third, the blending high, medium, and low grades across multiple processing destinations of the value chain are also considered by KPI-COSMO instead of pre calculated economic values of blocks. Therefore, the pit limit generated by KPI-COSMO is not only physically different, but also usually larger (around 25%) than the conventional pit limits.

Yes. KPI-COSMO has a variety of scheduling constraints that account for maximum slope angles along different azimuths, minimum mining width, maximum annual vertical advancements in the pits, etc. in order to generate optimized block-based extraction sequences that can be used as inputs for the open-pit mine design process. These constraints can be tailored for each geotechnical zone within the mine.

The conventional long-term open-pit mine schedulers usually rely on pushback-bench-panel approach, that is, after the pushback design, blocks within the same pushback and bench are grouped into one or multiple user-defined panels. These panels are then assumed to be homogeneously mined based on their inventories of different grade-bins. This large-scale aggregation of mining blocks within a panel misrepresents the selectivity and accessibility of materials to be extracted in each year. KPI-COSMO generates optimized extraction sequences based on the actual blocks from the input block models. This approach combined with the scheduling constraints of KPI-COSMO (slope angles, minimum mining width, maximum annual vertical advancements, etc.) reflect the expected mining selectivity and the supply of material from open-pits.

Material Destination / Handling

Cut-off grades are conventionally optimized independently from the long-term mine production schedule, which means that a schedule may no longer be optimal or feasible if the cut-off grade is modified. These pre-defined cut-off grades also do not take into account inherent uncertainty in grade and material types and the complex material blending that happen across the mineral value chain. This has an adverse effect on the NPV. KPI-COSMO enables the user to simultaneously optimize the cut-off grades and the schedules accounting for the uncertainties in the available mineral resources and multiple operational capacities in the value chain. This leads to significant improvement in NPV compared to the conventional cut-off grades.

The multiple material stockpiling, blending, processing, and refinery across the mineral value chain are characterized by highly non-linear transformations. Conventional long-term mine planning software usually rely on linearization simplifications that are unable to deal with complex non-linearities. KPI-COSMO on the other hand enables inputting simulations of geometallurgical properties and non-linear recovery and throughput curves for processing facilities, as well as modeling the homogenization occurring in the stockpiles, heap leach, etc. This ability contributes to more accurate and realistic optimized production forecasts including the NPV and qualitative product metrics.

Waste management is governed by the supply of material within the pits, economic parameters (metal prices, hauling costs, etc.), and environmental aspects (reduction of acid-generating rocks, waste dump footprint and monitoring, etc.). It is critical aspect of long-term mine planning. KPI-COSMO allows the user to properly model costs of haulage, acid neutralization, site-monitoring and environmental constraints. Additionally, KPI-COSMO’s simultaneous optimization of the cut-off grade policy while using the geostatistical simulations that better represent the spatial distribution and variability spatial distribution within the mineral deposits, which includes materials to be potentially dumped as waste.